Electrostatic Discharge

Depending on voltage i.e. the number of volts, this phenomenon can be:

- felt over over 3000 V

- heard over 5000 V

- seen in the shape of a spark or flash over 10000 V

ESD is the sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown. It can result in building up a high voltage which may cause components destruction at every phase of manufacturing, testing, transport or usage.

Protection from ESD is a system ensuring the safety of electronic components sensitive to electrostatic discharge. Using packaging made of materials marked by proper electrostatic qualities is an important component of the system.

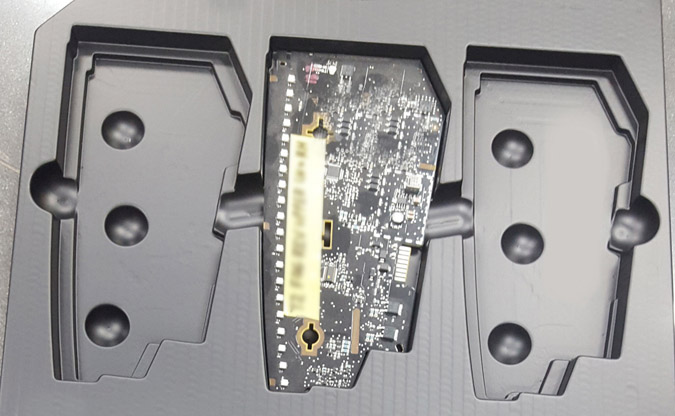

A tray which positions printed circuit boards should be made with a material with clearly marked surface resistance parameters. Professionally made transportation tray guarantees products optimal protection during packaging, storage, transport and assembly processes.

ESD packaging is rising as preferred method of packaging for products which are not at direct risk of Electromagnetic Discharge, however, being in contact with various electronic parts during different phases of assembly process. Products packed in that way can be transported to Electrostatic Protected Areas without necessity of moving them to safe packages in an assembly plant.

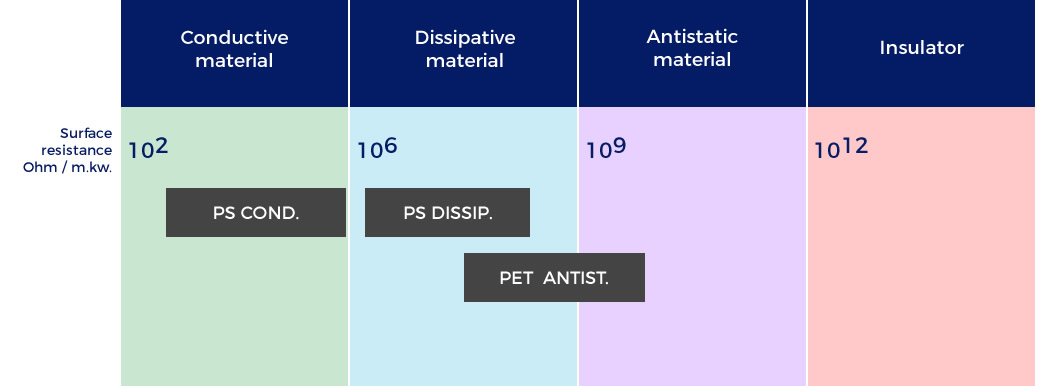

We offer a wide range of materials protecting against Electrostatic Discharges: conductive, dissipative and electrostatic. The first two are available in black while electrostatic material may be transparent. Material thickness ranges from 0,5 mm to 8,00 mm.

In compliance with company Quality Management System rules producer of an ESD material is obliged to attach a report concerning the surface resistance test for every shipment of the ESD material. Additionally material is checked second time on delivery to a warehouse. A final resistance check is carried out on ready trays prior to dispatch.