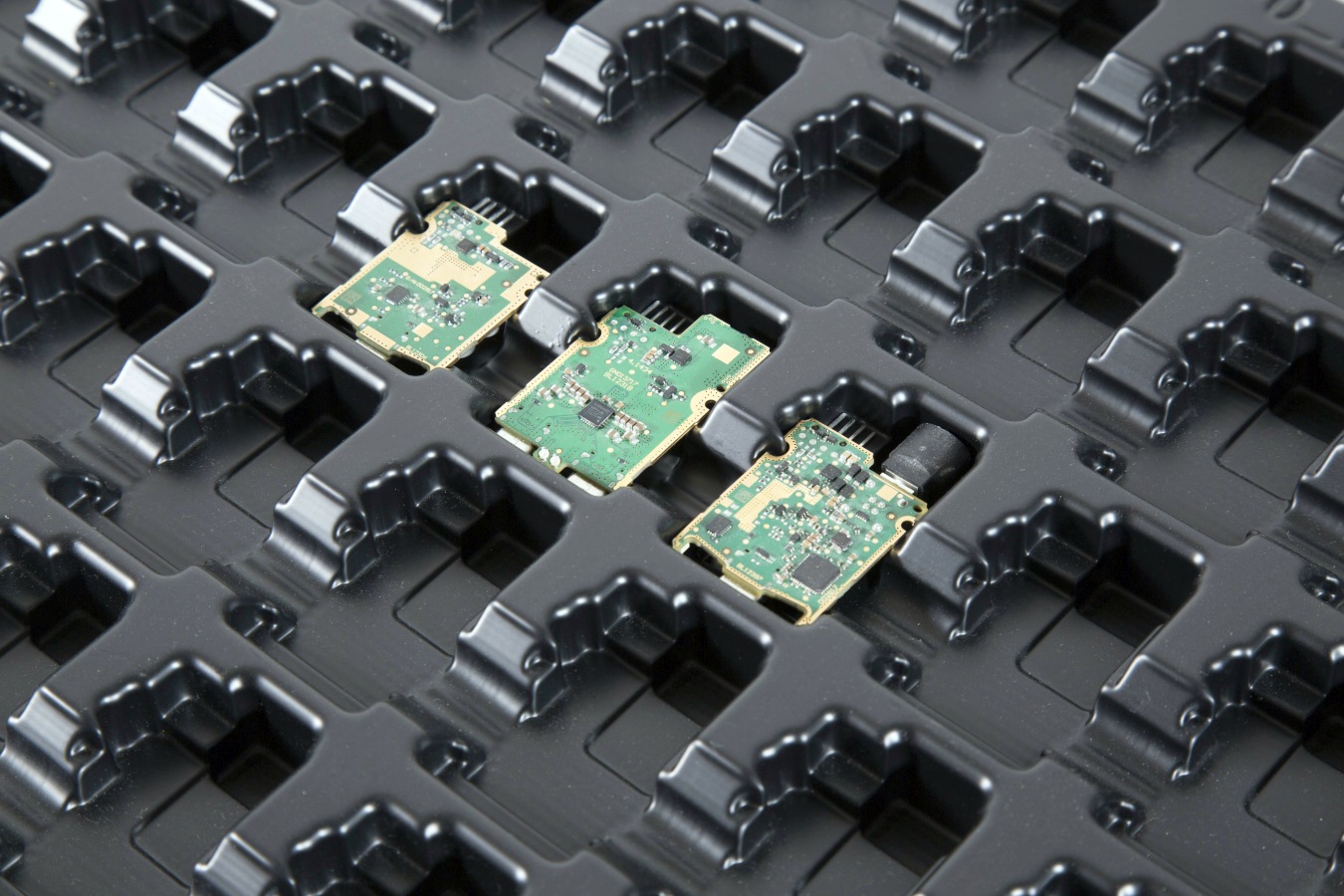

Electronics

We are ready to produce trays as per your own project. However, we can also prepare a full packaging concept or packaging systems based on your project details.

We can suggest a logistically suitable size of transportation trays and optimal type and material thickness.

Inter-seat and inside facility trays are made in a way that allows their usage for the whole period of the project duration (up to a few years).

Trays construction should meet local logistic conditions that guarantees work ergonomics and continuous quality of the packaging and transportation processes.

Single-use trays are made in an economic way that meets quality standards and full safety of the products transported.

Single-use trays are utilized in situations when their re-use is not economically and qualitatively effective.

Multi-use trays are constructed with a project duration in mind. A very relevant question is taking into consideration all essential conditionings referring to transportation, storage and utilization of products in target assembly companies.

Selection of materials that guarantee maintaining or reinstating a desired product cleanliness prior to next packaging cycle is extremely important.

Professional project analysis, full identification of protected areas and potential resting spots in particular, allows creating universal trays that can be used to position products of various shapes, products at various assembly stages or products of different versions of final assembly.

Depending on types of the products packed and their logistical destination, we offer a full material range to produce packaging.

Apart from black trays made of conductive and distracting PS, we offer colourless antistatic PET material.

Special construction of production forms allows production of transportation trays that are suitable for automatic positioning on assembly lines, cooperation with manipulators and product application.

Tough and permanent consolidated packaging.

Cygpak is an alternative to the whole range of containers and transportation boxes. Its advantage is reflected in the possibility of removing polypropylene wrapper and reduction of the empty package volume by 80 % in return transport.

Another advantage is a possibility of ordering a package dedicated to a project realized of any height up to 1200mm.

Dynamic and static stacking of Cygpak and utilizing them in high racking warehouses is also possible.