Product quality

Quality Management System

ISO 9001:2015

Our goal is to produce the highest quality, innovative, individualized, environmentally friendly packaging and transport systems using modern production and management technologies.

In the production process, Cygnus follows principles consistent with the regulations of Occupational Safety and Health and Environmental Management.

All stages of the project implementation from concept through visualization, 3D modeling, prototyping, construction of production forms to the final production process take place in the Cygnus production plant in accordance with the guidelines of the Quality Management System.

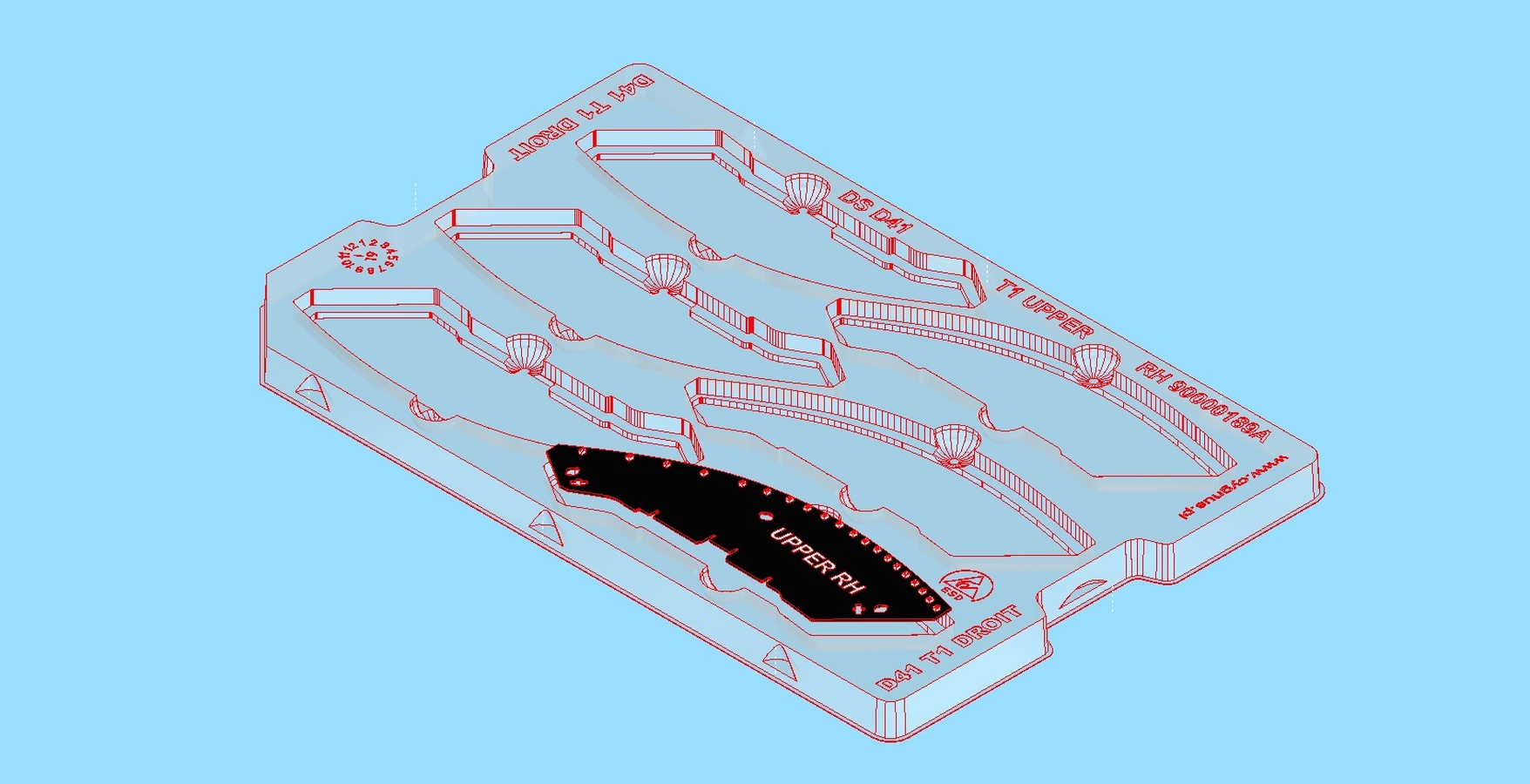

After decision about final concept of the tray, a visualization is prepared showing the details of the sockets and their mutual arrangement.

In justified cases, before preparing a full physical prototype, a “partial prototype” is prepared, covering several adjacent sockets. It allows at the initial stage of prototyping to choose the right solution: construction of the socket and the distance between them. On the next stage it will be presented in a full prototype that will be approved before starting production.

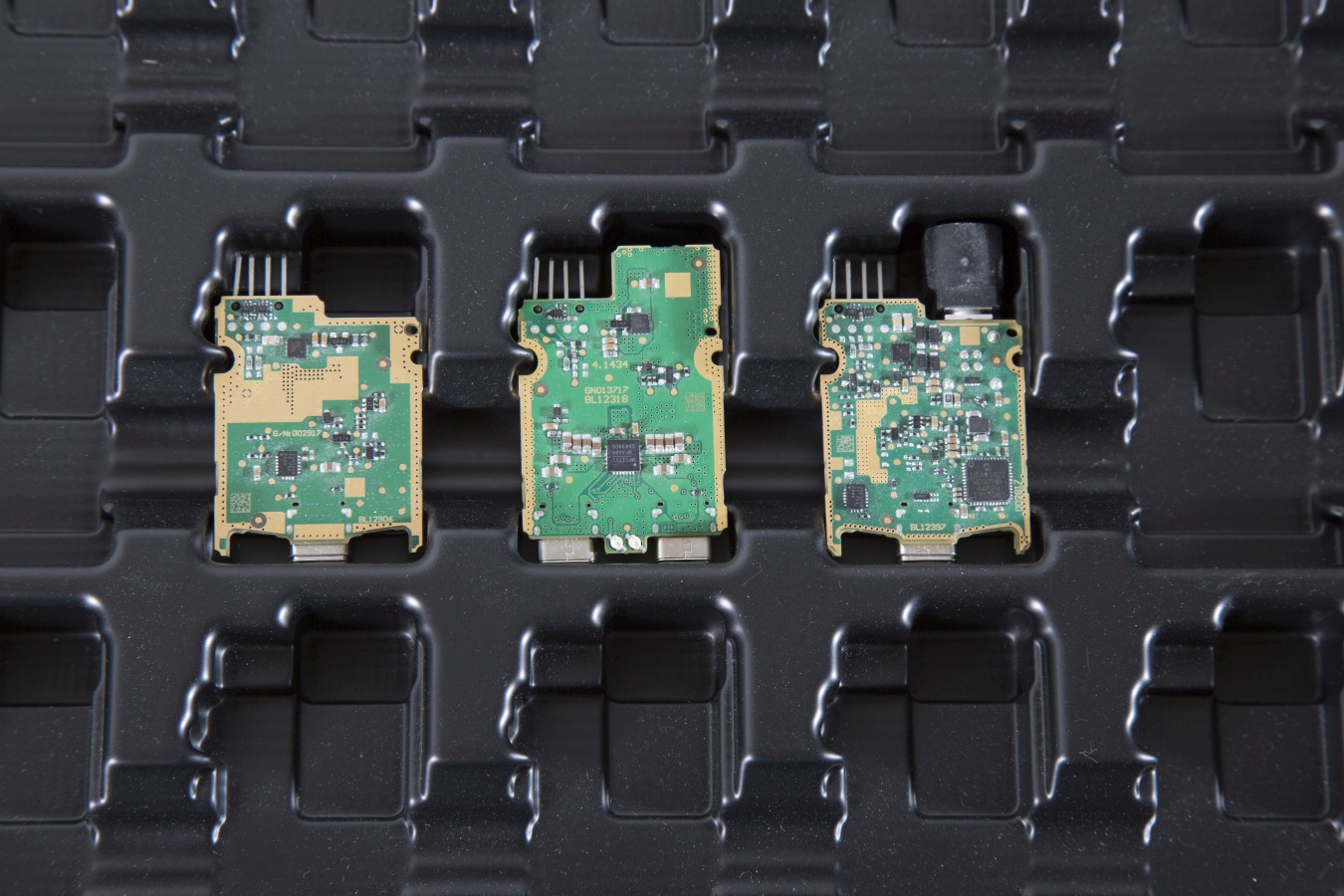

Accuracy and quality of the manufactured prototype is verified by checking the sockets with a physical product provided by the customer. In the absence of a product, the same effect can be achieved by using a printed replacement.

High quality of the manufacturing tools with a precise production process allow designing and creating trays with universal sockets. Universal sockets allow positioning products from different projects or at different assembly stages.

While building manufacturing instrumentation, we take into account the timeline of the project and quality requirements declared by the customer. Instrumentation at our disposal is secured and revitalized. It is covered by indefinite warranty for the entire duration of the project.